The metal sheets you get to witness in the market are the finished product. A lot of industrial procedures are adhered to bring it to this state. It then offers the much needed help for fabrication so that various metal shaping can be done. These sheets are derived by utilizing different materials like aluminium, copper, and more.

Modern Industrial Community Benefits From Use Of These Sheets

Today, sheet metal fabrication is credited for offering immense help to the industrial community. These sheets are in wide use in numerous manufacturing needs in areas like aircraft parts, construction materials, electronic parts, and more. As these sheets get used for varied construction materials, people and companies associated with the construction industry are more than happy to find a very cost-effective alternative.

They vehemently agree, this permits them to keep the costs at a low level. For instance, it aids them to keep the project costs to a minimal level when they choose these sheets to construct different industrial structures.

The Fabrication Procedure Deserves A Special Mention

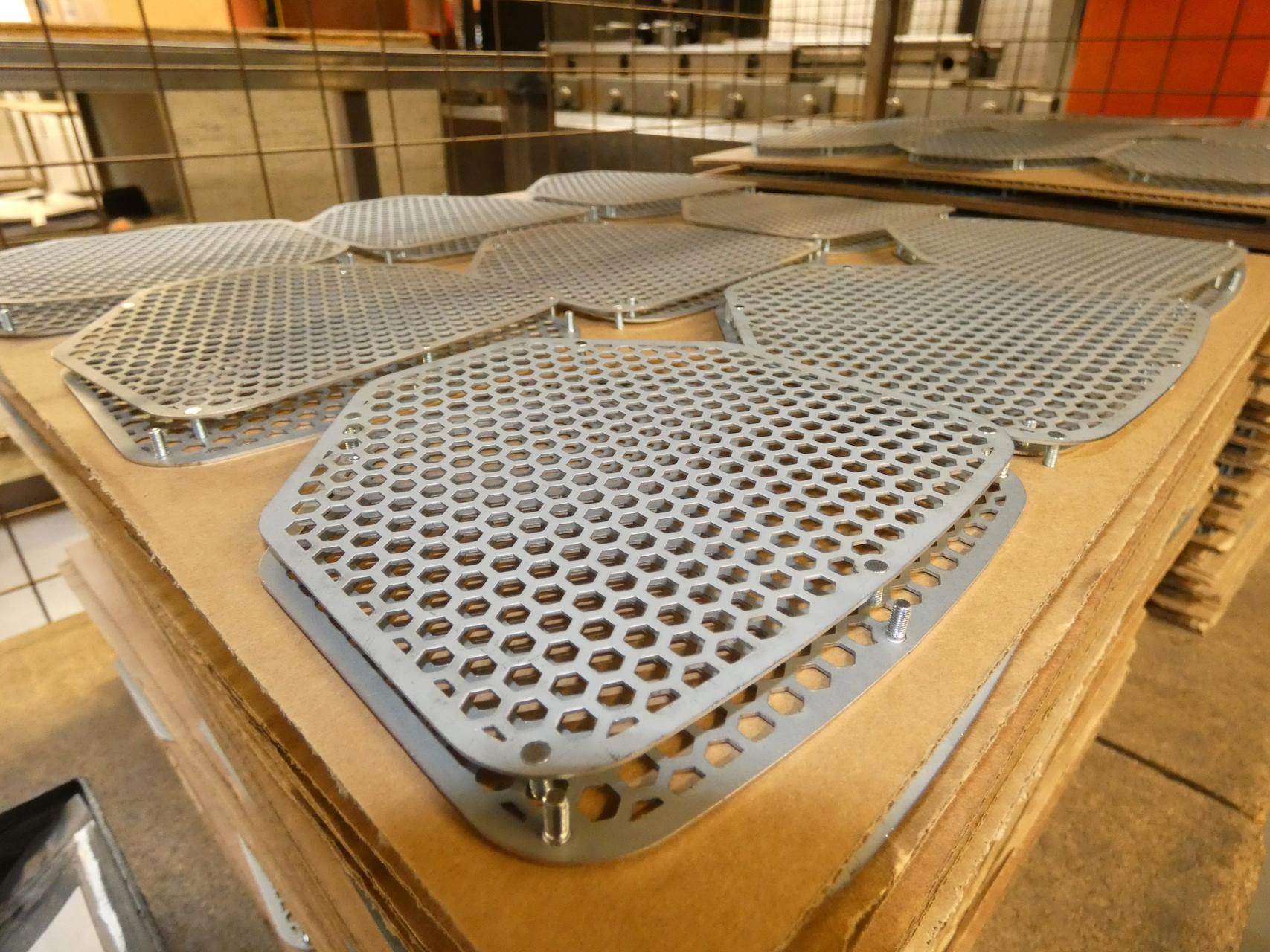

Like any other procedure, even this fabrication process is unique and involves various stages. For example, it has basically three significant stages – to cut, bend and assemble. In the first stage, the big-sized sheets are cut in different shapes or sizes. These are thereafter subjected to the process to get holes according to the stipulations provided in the design. Coming to the bending stage, all applicable sheets are then bent again according to the needs of the design to be achieved. In the third and final stage of sheet metal fabrication, a procedure like welding is duly adhered to assemble all components of the metal sheet.

Various Metals And Machines Are Employed To Accomplish The Fabrication Process

The fabrication process is totally unique and relies on a scientific approach. This is one reason why the use of rightful metal is necessary to take the process to its logical ends. Any wrongful use of a particular material fails to produce desired outcomes. Nevertheless, metals like aluminium and stainless steel are very commonly used.

Just like the selection of metal ought to be accurate, so is the case with the machines. For instance, punching machines are the best choice for cutting holes. Similarly, by using press brakes you can bend the sheet metal into desired shape and design. Lastly, you ought to employ welding machines to accomplish the objective of welding so that assembling can take place smoothly. It is only the presence of these types of machines and metals that ensures the fabrication process gets completed uninterrupted.